雙相不銹鋼結構型材

To produce Hyper-duplex /Super-duplex stainless steel Sections, we utilize laser fusion and laser hybrid welding welding methods. Our laser hybrid approach ensures greater reliability, process control and repeatability in duplex steel welding. With this method, the corrosion resistance of the weld and heat-affected zone is equivalent to that of the base metal. During this production process, parent materials are fused together, just like our standard laser fusion process, to form a single unitary structure. The fused structure has the mechanical properties of the parent material. In addition, extensive destructive testing was performed, showing that the material itself can bend or break before the weld area itself.

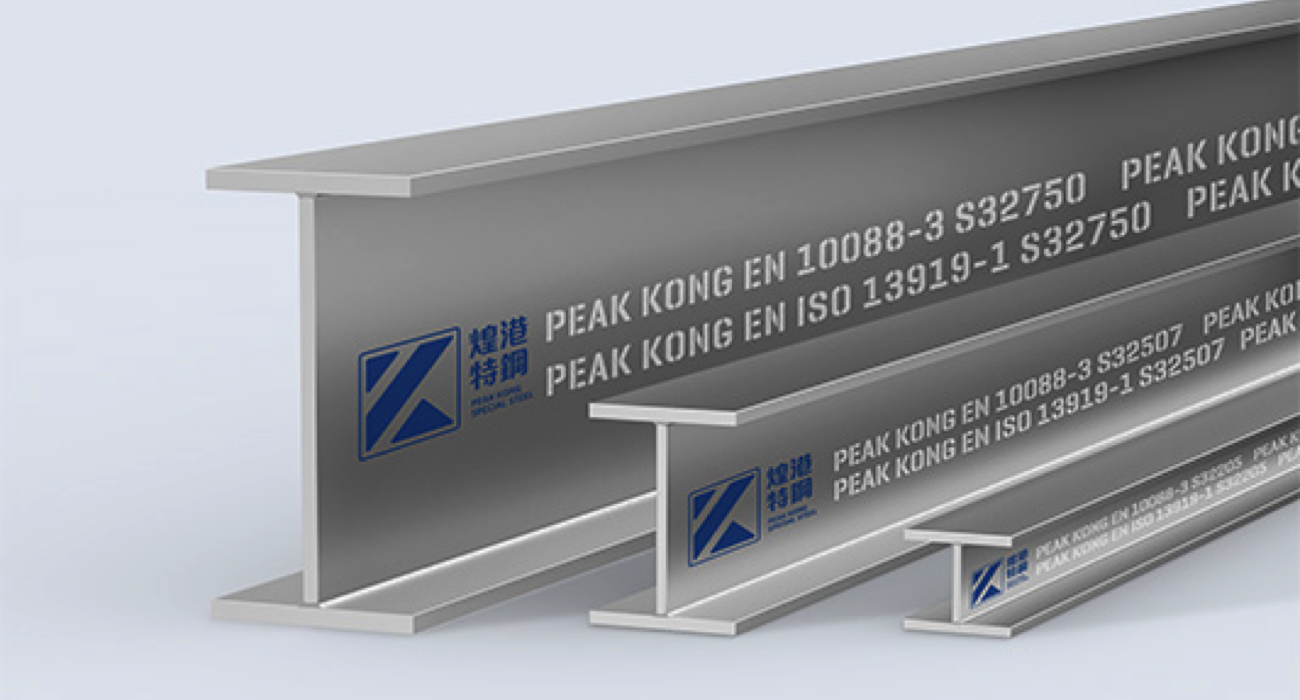

Through laser welding we are able to produce all structural standard structural shapes. These include stainless steel channels, beams, angles, stainless steel H-beams, pipes, and even duplex stainless steel custom profiles. Our most commonly used duplex stainless steel is 2205, but we also produce 2101 and 2507 super duplex alloys.

Many architects, Engineers, manufacturers, etc. are well aware of the benefits of using Hyper-duplex /Super-duplex stainless steel Sections in their projects. No other metal can offer the corrosion resistance that stainless steel does, especially in harsh and corrosive environments. Duplex stainless steels offer twice the yield strength of austenitic and ferritic stainless steel grades. Furthermore, they can do this without sacrificing corrosion resistance and other mechanical and physical properties.

One area where the use of Hyper-duplex /Super-duplex stainless steel Sections is increasing is in the marine environment, such as boating and offshore oil rigs. These projects may have originally used 316/L stainless steel. But over time, even 316/L may not survive extreme environments or when the material is fully immersed in water. Some other areas where Hyper-duplex /Super-duplex stainless steel Sections may come into play is in structural support. Most applications are in process plants or chemical plants. Architecture and architectural design also rely on duplex steel Sections for their strength and appearance. We can also see applications for duplex stainless steel in wastewater and desalination plants, pulp and paper production, and transportation.